- Perfect packing for essential oil , body oil and cosmetic oil.

- The white glass material is glittering and translucent, non-toxic and tasteless, safe and healthy.

- The products can be customized according to your requirements, such as decal, silk printing, electroplating, coloring and customised logo or label.

| Materials | Glass |

| Color | Any color is available based on demands. |

| Customers' logo | Accepted |

| ODM | Welcome |

| Surface Treatment | silkscreen; hot stamping;frosted;decal;painting;electroplating;spray;label;sticker,etc. |

| Lid/Cap | cork;rubber;aluminum screw cap;glass stopper, etc. |

| MOQ | 1. For ready stock, MOQ is 1,000pcs 2. For customized products, MOQ is 3000-20,000pcs |

| Lead time | 1. For ready stock : 7 days after receiving payment. 2. For products out of stock : 25 ~ 40 days after receiving payment. |

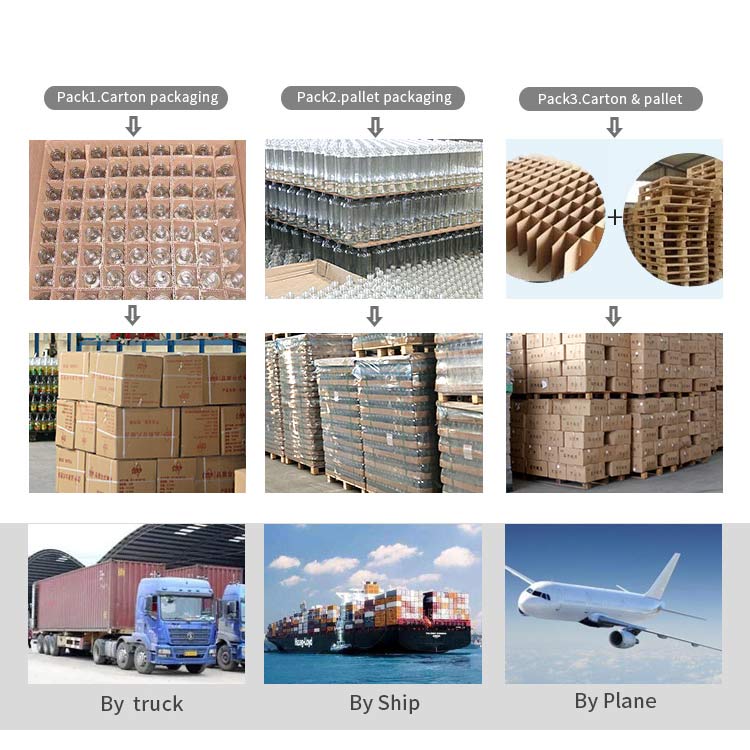

| Packaging | standard carton;gift box;colorful box; white box;export pallets;special requirements on packing,etc. |

| Sample time | 3 days if samples are in stock 3 to 15 days if samples needed to be customized |

| port | Shanghai/Qingdao/ Lianyungang, China |

| Shipping | by sea, by air, by express, and so on. It's up to you |

- Perfect packing for essential oil , body oil and cosmetic oil.

- The white glass material is glittering and translucent, non-toxic and tasteless, safe and healthy.

- The products can be customized according to your requirements, such as decal, silk printing, electroplating, coloring and customised logo or label.

Click here for more information

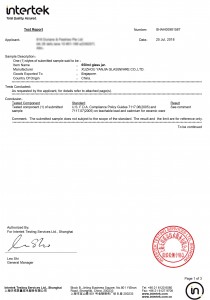

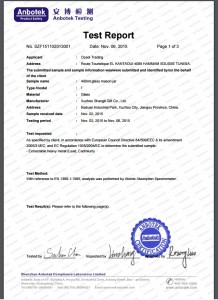

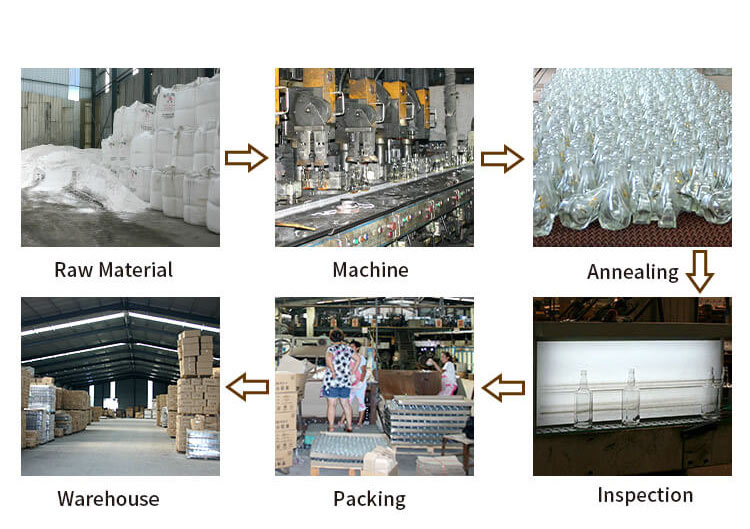

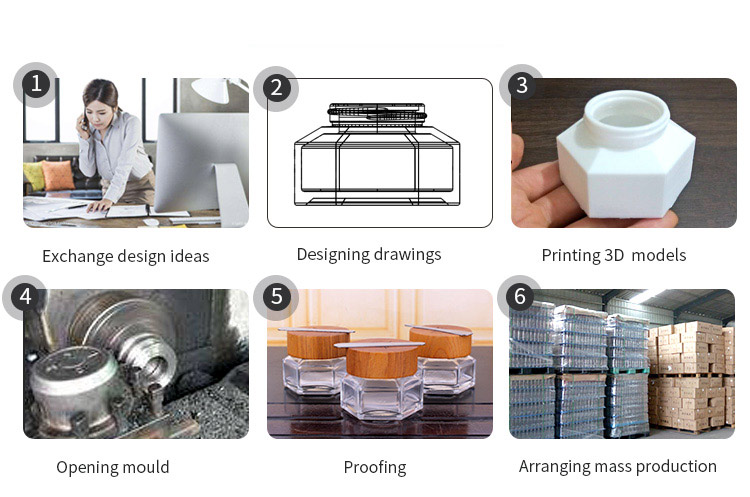

If you need to customize a new product, our professional designers can draw up design drawings according to your proposal. After the drawings are approved, a special merchandiser is responsible for sending the drawings to the mold factory for making the mold. After the mold is finished, it will be sent to the factory. The factory can make the bottle samples for you. We will send the samples to you for confirmation. After the samples are confirmed, they can be produced. We will also be responsible for the subsequent packaging, product quality inspection and so on. In general, our company's mode is to integrate design, production, packaging, quality inspection and all-round services.The production process of our products is: Raw material selection and batching ( preparation of the required batches from the batching workshop) → Melting (transported from the conveying equipment to the melting workshop for high temperature melting)→Molding (feeding machine supplies liquid glass to the molding equipment, make the product with the required shape) → Annealing (the product is sent to the annealing furnace for annealing treatment through bottle conveying and bottle pushing machines) → Inspection → Packaging → Warehouse. After the product is formed, quality inspection is performed by professional staff, and qualified products are packed and stored. The entire process is strictly manufactured in accordance with the requirements of IS09001: 2000 standard quality management system certification. The product quality is strictly controlled and controlled at various levels.The high-quality products have won the favor of domestic and foreign customers. The products are exported to the United States, Russia, Canada, South Korea, India, Australia and other countries.Pallet packaging: We put the product on the tray, and then put the partitions on top of each other for stacking. After packaging, it is wrapped around for the purpose of dustproof and waterproof. Carton packaging: add partitions in the packaging box to separate the products individually to prevent glass bottles from colliding, rubbing, and breaking during transportation. We also apply PP bag on each bottle for double protection according to customer requirements. In order to avoid collisions between cartons, our cartons will be packed in pallets wrapped with plastic film, so don't worry about the bottles breaking during transportation. Transportation: We have a complete service system that can provide consignment, automobile, train, container, water, and air transportation services.

If you need to customize a new product, our professional designers can draw up design drawings according to your proposal. After the drawings are approved, a special merchandiser is responsible for sending the drawings to the mold factory for making the mold. After the mold is finished, it will be sent to the factory. The factory can make the bottle samples for you. We will send the samples to you for confirmation. After the samples are confirmed, they can be produced. We will also be responsible for the subsequent packaging, product quality inspection and so on. In general, our company's mode is to integrate design, production, packaging, quality inspection and all-round services.The production process of our products is: Raw material selection and batching ( preparation of the required batches from the batching workshop) → Melting (transported from the conveying equipment to the melting workshop for high temperature melting)→Molding (feeding machine supplies liquid glass to the molding equipment, make the product with the required shape) → Annealing (the product is sent to the annealing furnace for annealing treatment through bottle conveying and bottle pushing machines) → Inspection → Packaging → Warehouse. After the product is formed, quality inspection is performed by professional staff, and qualified products are packed and stored. The entire process is strictly manufactured in accordance with the requirements of IS09001: 2000 standard quality management system certification. The product quality is strictly controlled and controlled at various levels.The high-quality products have won the favor of domestic and foreign customers. The products are exported to the United States, Russia, Canada, South Korea, India, Australia and other countries.Pallet packaging: We put the product on the tray, and then put the partitions on top of each other for stacking. After packaging, it is wrapped around for the purpose of dustproof and waterproof. Carton packaging: add partitions in the packaging box to separate the products individually to prevent glass bottles from colliding, rubbing, and breaking during transportation. We also apply PP bag on each bottle for double protection according to customer requirements. In order to avoid collisions between cartons, our cartons will be packed in pallets wrapped with plastic film, so don't worry about the bottles breaking during transportation. Transportation: We have a complete service system that can provide consignment, automobile, train, container, water, and air transportation services.